Reasons for pickling:

Hot rolled sheets are pickled for two reasons.

1. The sheets obtained from the process of cleaning the oxide layers and pickling are of considerable quality and appearance.

2. Some oxide shells on the surface of the sheet are hard and anti-wear, so if the cold rolling process is carried out without pickling and deoxidizing the sheet, it will cause the cold rolling rollers to abruptly abrade and exit the tolerance and it makes the cold rolling process all the more difficult. If the adhesion of the oxide shells to the surface of the sheet is loose and weak, this complicates the process. Therefore, to prepare the sheet for cold rolling process, it is necessary to pickle the surface of the sheet before the cold rolling process.

Applications of acid cleaning sheets:

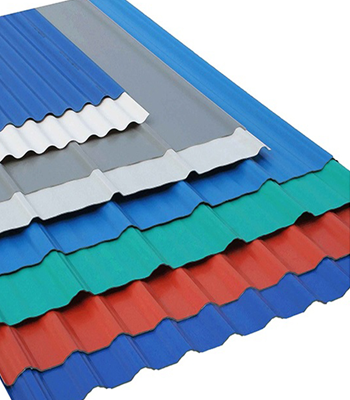

Construction Uses: Production of Pipes and Profiles and…

Automotive: Car parts and wheels for automobiles and automotive parts and interior parts such as rims and chassis

Tubing Industries: Production of water, oil and gas pipelines, production of gas and pressure vessels, re-shaping of galvanized products, cold forming and deep stretching of gas cylinders

Dimensions of pickling sheet:

Pickling sheets are produced in two rolls and sheets.

Roll widths are usually 100 cm and 125 cm.

Pickling sheets have dimensions of 1000mm * 2000mm and 2500 mm * 1250mm.

Reviews

There are no reviews yet.