Description

Specifications :

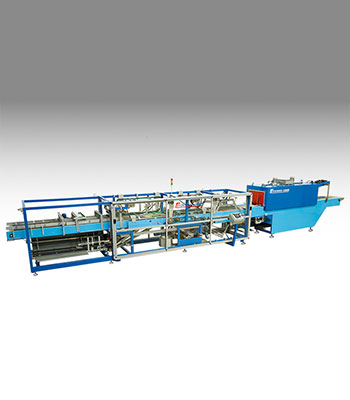

- The machine has two compartments , configuration table , and heating tunnel.

- The configuration table is arranging the final pack(maximum3*4) as desired .

- The separation and the distance between the two packages are easily controllable and completely mechanical .

- The machine arranges two packages at a time in each cycle and performs the operation of the wrapping on both packets.

- In this machine, only a plastic pad for both packages is used and the nylon separation operations are performed for two coils simultaneously with cutter and angled roller bearings.

- The machine, after cutting the plastic, closes it so that its edges overlap (overlapped).

- The machine does not have Sewing Blade , and the plastic edges melt together when the packet passes through the thermal tunnel.

- In the tunnel section, the hot air flow is performed by a U-shaped blade element and a radial fan.

- In the middle of the tunnel there is a height adjustable aeration channel, which can be set up depending on the container.

Machine speed:

the Speed of machine is 50 packs per minutes

Control mechanism :

The machine is fully automatic in operation and is equipped with electronic control (PLC) , Touch screen monitor and electric speed control(frequency inverter)

Machine has control equipment for control Air Flow and direction , Tunnel temperature , Detection of the presence or absence of a container and nylon and show error message

Fabrication Materials :

All electric , electronic and pneumatic components used in machine is japanese and European made .

| Container height ( mm ) : 100-350 |

| Container diameter ( mm ) : 50-104 |

| Output ( packs/min ) : 50 |

| Air Cunsumption : 40 NL/min |

| Power Cunsumption : 80 KW |

Reviews

There are no reviews yet.