Types of zinc metal deposition methods:

1. Hot dip galvanizing

2. Electric galvanizing

3. Thermal spraying

Galvanized manufacturing process

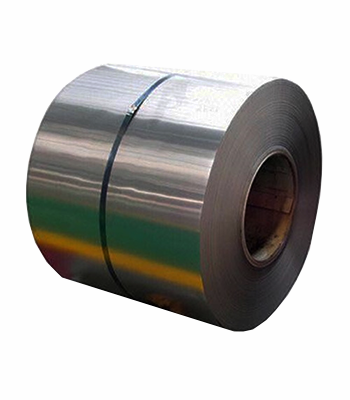

In the hot-dip galvanizing method, the production of galvanized sheet improves the corrosion resistance of the steel sheet due to the lower corrosion rate of the coating material. Therefore, this is the most common and well-known way to protect steel sheets against corrosion.

The process of producing galvanized sheets is a relatively long process that heat treatment also includes the initial clearance of contaminants then the main cleaning step is done. The obtained sheet enters the preheating furnace and is coated with molten metal. The thickness of the galvanized sheet coating depends on the size and shape of the drying system and the gas blowing rate and other factors. It is worth noting that precise measuring instruments such as X-rays are used to monitor the actual coating thickness.

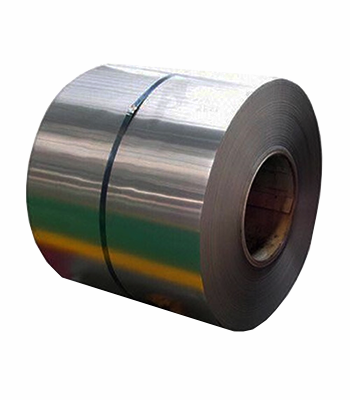

The final product is packaged in the form of coils or sheets with specified lengths at the end of the line. Isfahan Mobarakeh Steel Company is one of the production units of galvanized sheet in Iran.

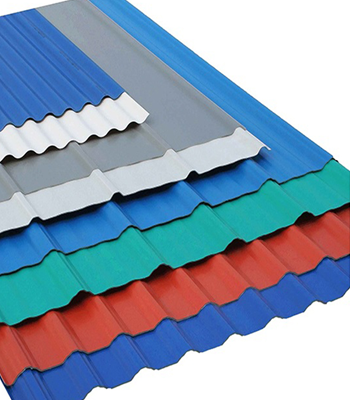

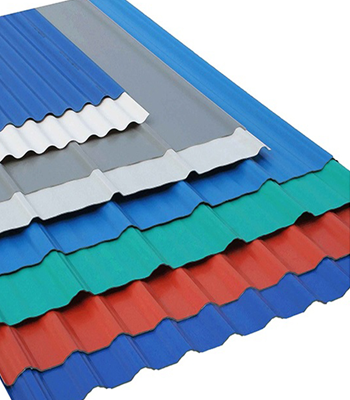

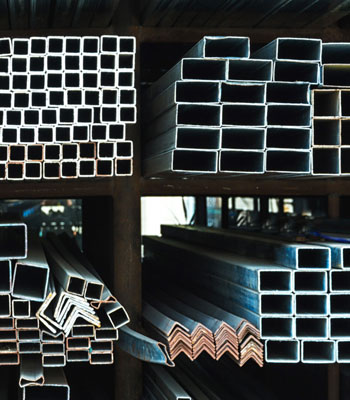

The main uses of galvanized sheet:

– Water storage tanks

– Auto parts

– Components of agricultural machinery

– Home Appliance components like refrigerators, heaters and air coolers

– Metal roofs, panels and electrical boards

Reviews

There are no reviews yet.