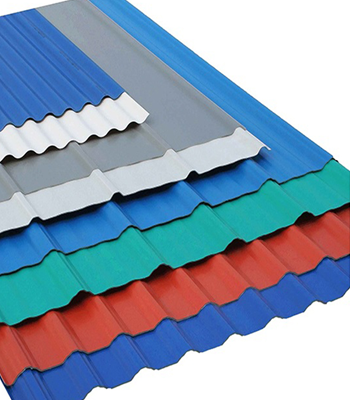

Galvanized sheet coloring is essential if the sheet is in proximity with acidic and alkaline materials. Its coloring is similar to that of low carbon steel sheets.

When coloring the surface of the sheet should be completely clean and before coloring, the preparation and infrastructure of the sheet must be done to be able to absorb color. The strength of the primer layers should also be checked.

– First step: cleaning the galvanized sheet

Sheets should be free of any dust, dirt and grease. Fabric impregnated with Thinner can be used to remove grease and Oily substances and replaced it regularly. If there is rust, it can be gently removed by soft sanding.

– Second step: color substrate of color galvanized sheet

Infrastructure should be designed to be resistant to the environmental conditions which the sheet is located. The primer on the surface of the steel sheet is quite different from the primer on the color galvanized sheet. Infrastructure is usually done with brushes, rollers and spray on the sheet.

Final coloring of galvanized sheet:

Galvanized sheet coloring depends on the type of sheet application and the environment in which the sheet and color are located. Before coloring, color compatibility and adhesion should be checked. Factories use furnace colors.

When coloring, the color combination and the color retention time should be considered to achieve the desired result.

Preparation steps for galvanized sheet:

1. Cleaning by spraying the cleaning solution on the sheet

2. Wash the sheet with water

3. Preparation of sheets

4. Re-wash the sheet

5. Washing and deactivation

Inactivation operation on the galvanized sheet reduces the chance of scurf (white rust). The most popular brands of galvanized sheets are STELVETITE and COLORCOAT steel sheets.

Reviews

There are no reviews yet.