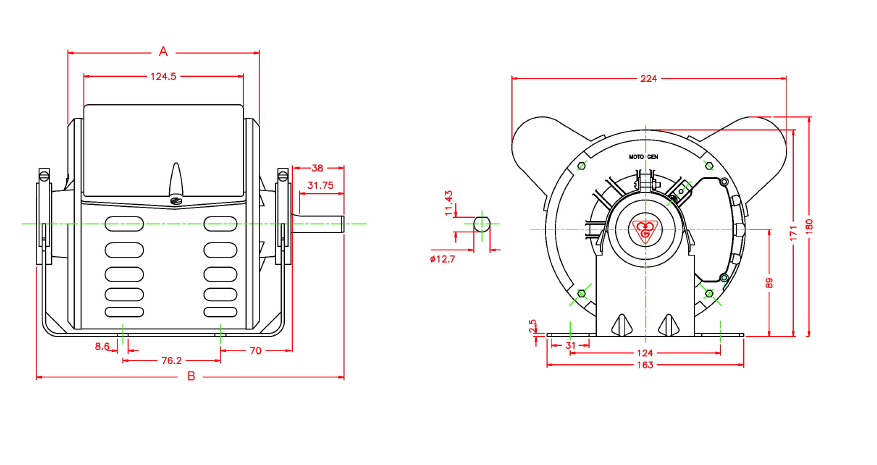

1/5 HP Tow-Speed Evaporative Cooler Elctro Motors

0,00 €Product Specification

| Type | Output Power | Output Power | Speed in rated load | Rated Current | Rated Torque | Power factor | Starting / Rated Current | Starting / Rated Torque | Break down / Rated Torque | Weight of foot mounting types | Capacitor Run | Capacitor Run | Poles |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CR 80-4P | 0.18 | 1/5 | 1400 -2Speed | 1.8/1.6 | 1.2 | 0.96 | 2.18 | 1.05 | 2.27 | 5.370 | 8/8 | 400 | 1 |

| CR 80-4P-S | 0.18 | 1/5 | 1400-2Speed | 1.5/1.2 | 1.2 | 0.94 | 2.3 | 1.05 | 2.27 | 5.380 | 8/8 | 400 | 1 |

Axial Flow Electropump (ISO 5199)

0,00 €Usages:

- Water

- Wastewater

Product features

- Wet-well, single-stage submersible motor pumps

- in discharge tube, with single-entry axial propeller

- in ECB design.

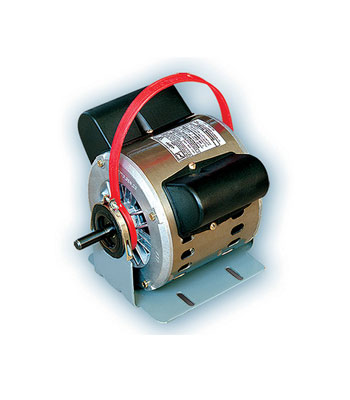

Burner Electro Motors

0,00 €Product Specification

| Type | Output Power | Rated Voltage | Speed in rated load | Rated Current | Efficiency (%) | Power factor | Starting / Rated Current | Starting / Rated Torque | Break down / Rated Torque | Capacitor Run | Capacitor Run | Poles |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EB90-21A | 0.06 | 220 | 2690 | 0.55 | 52 | − | 2.3 | 0.8 | 1.6 | 4 | 400 | 1 |

| EB90-21B | 0.09 | 220 | 2800 | 0.75 | 57 | 0.96 | 2.8 | 0.82 | 2 | 5 | 400 | 1 |

| EB90-21C | 0.11 | 220 | 2700 | 0.85 | 60 | − | 2.4 | 0.65 | 1.4 | 6.3 | 400 | 1 |

| EB90-21D | 0.125 | 220 | 2730 | 1.01 | 56 | 1 | 2.64 | 0.82 | 1.67 | 6.3 | 400 | 1 |

| EB90-21E | 0.15 | 220 | 2710 | 1.15 | 61 | − | 2.8 | 0.63 | 1.6 | 6.3 | 400 | 1 |

| EB90-21F | 0.18 | 220 | 2700 | 1.25 | 67 | − | 3 | 0.43 | 1.4 | 6.3 | 400 | 1 |

| EB90-21G | 0.24 | 220 | 2700 | 1.7 | 66 | 0.97 | 3 | 0.35 | 1.44 | 8 | 400 | 1 |

Capacitor Run Two-Speed Evaporative Cooler Electro Motors

0,00 €Product Specification

| Type | Frame size | Output Power | Output Power | Rated Voltage | Speed in rated load | Rated Current | Rated Torque | Power factor | Starting / Rated Current | Starting / Rated Torque | Break down / Rated Torque | Capacitor Run | Capacitor Run | Poles |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CR 56-4/6-Col | 56 | 0.187/0.062 | 1/4 / 1/12 | 220 | 1425/950 | 1.58/0.7 | 1.25/0.62 | 0.97/0.95 | 3.1 | 1.17 | 2.1/2.25 | 10/8 | 400/400 | 1 |

| CR 56-4/6-D01 | 56 | 0.25/0.7 | 1/3 / 1/10 | 220 | 1425/950 | 2.3/1 | 2.1/0.98 | 0.96/0.98 | 3.69 | 1.14 | 1.85/0.97 | 16/8 | 400/400 | 1 |

| CR 56-4/6-E01 | 56 | 0.37/.0124 | 1/2 / 1/6 | 220 | 1425/950 | 3.5/1.3 | 3.2/1.25 | 0.94/0.93 | 3.65 | 0.88 | 1.61/1.76 | 20/12.5 | 400/400 | 1 |

| CR 56-4/6-F01 | 56 | 0.55/0.18 | 3/4 / 1/4 | 220 | 1425/950 | 3.75/1.69 | 3.75/1.87 | 0.99/0.97 | 3.6 | 0.56 | 1.73/1.25 | 25/12.5 | 400/400 | 1 |

Capacitor Run-Capacitor Start Evaporative Cooler Electro Motors

0,00 €Product Specification

| Type | Frame size | Output Power | Output Power | Rated Voltage | Speed in rated load | Rated Current | Rated Torque | Power factor | Starting / Rated Current | Starting / Rated Torque | Break down / Rated Torque | Inertia moment | Capacitor Run | Capacitor Run | Capacitor Start | Capacitor Start | Poles |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CRS 56-4/7 | 56 | 0.187/0.062 | 1/4 / 1/12 | 220 | 1425/950 | 1.58/0.74 | 1.25/0.62 | 0.97/0.95 | 3.5 | 1.68 | 2.1/2.25 | 0.00172 | 12/6 | 400/400 | 15 | 250 | 1 |

| CRS 56-4/8 | 56 | 0.25/0.083 | 1/3 / 1/9 | 220 | 1425/950 | 2/0.9 | 1.67/0.83 | 0.98/0.96 | 4 | 1.6 | 2.26/0.97 | 0.00215 | 16/8 | 400/400 | 20 | 250 | 1 |

| CRS 56-4/9 | 56 | 0.37/0.124 | 1/2 / 1/6 | 220 | 1425/950 | 2.9/1.18 | 2.5/1.25 | 0.95/0.97 | 3.44 | 1.52 | 2.2/1.76 | 0.002557 | 20/10 | 400/400 | 25 | 250 | 1 |

| CRS 56-4/10 | 56 | 0.55/0.18 | 3/4 / 1/4 | 220 | 1425/950 | 3.68/1.69 | 3.75/1.87 | 0.99/0.97 | 3.2 | 1.53 | 1.6/1.25 | 0.003324 | 25/12.5 | 400/400 | 30 | 250 | 1 |

Heavy Slurry pump (ISO 5199)

0,00 €Usages:

- Steel complex and mining

Design:

Horizontal, radially split volute casing pump in back pull-out design, with impeller adapted to meet application requirements, single-flow, and single-stage.

Special Features:

- Reinforced, axially adjustable bearing assembly on all pumps.

- Shaft seal: mechanical seal integrated into the casing cover, or gland packing.

- Even cast iron pumps are supplied with pump internals (impeller and wear plate) made of wear-resistant ERN (nickel cast iron).

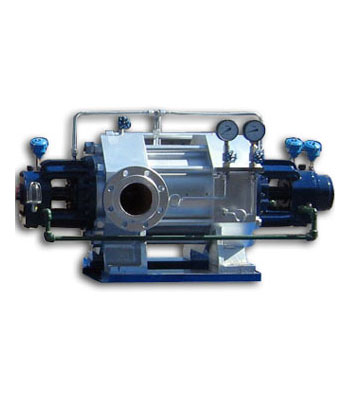

High Pressure Pump (ISO 5199)

0,00 €Usages:

- Fire Fighting

- Water

Product features

- Horizontal or vertical, long or close-coupled,

- multistage centrifugal pump in ring-section design,

- with axial or radial suction nozzle, cast radial impellers.

Parker Hydraulic Cylinder

0,00 €| Model : | – |

| Description : | PARKER Hydraulic Cylinder, Powerful, Very accurate and fast, professional and High strength, high quality, the ability to work in extreme conditions, ideal for complex tasks, High pressure, these Cylinders in sizes offered these cylinders are offered in different sizes |

Company name : | Padideh Hydraulic & Pneumatic |

| Packaging : | Box |

Minimum order : | 1 |

| Standard : | – |

Production power : | 100 |

| Payment type : | Cash |

Source : | www.hydpne.com |

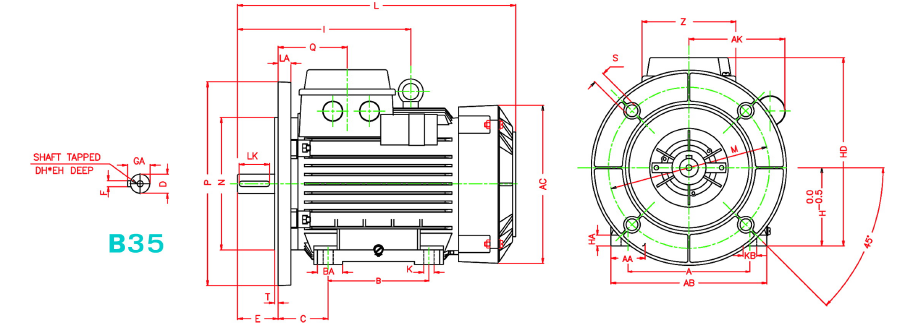

Phase Capacitor Run Electro Motors

0,00 €Dimension (Foot mounting – Flange mounting)

| Frame No.IEC | T | S | P | N | M | LA | AK | HD | H | C | B | BA | K | KB | AB | A | AA | HA | AC | Z | Q | I | L | E | EH | DH | GA | LK | F | D | FLANGE SYS.IEC 72-1 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 56 | 3 | 7 | 120 | 80 | 100 | 8 | 105 | 145 | 56 | 36 | 71 | 19 | 6 | 10 | 112 | 90 | 22 | 10 | 106 | 76 | 55.5 | – | 189 | 20 | – | – | 10.2 | 12 | 3 | 9 | FF100 |

| 63 | 3 | 10 | 140 | 95 | 115 | 10 | 106 | 158 | 63 | 40 | 80 | 25 | 7 | 10 | 125 | 100 | 25 | 10 | 123 | 76 | 54.5 | – | 214 | 23 | – | – | 12.5 | 12 | 4 | 11 | FF115 |

| 71 | 3.5 | 10 | 160 | 110 | 130 | 10 | 110 | 175 | 71 | 45 | 90 | 18 | 7 | 10 | 140 | 112 | 28 | 11 | 138 | 76 | 58 | – | 241 | 30 | – | – | 16 | 18 | 5 | 14 | FF130 |

| 80 | 3.5 | 12 | 200 | 130 | 165 | 12 | 130 | 194 | 80 | 50 | 100 | 25 | 10 | 14 | 160 | 125 | 35 | 11 | 156 | 96 | 68.5 | – | 276 | 40 | – | – | 21.5 | 25 | 6 | 19 | FF165 |

| 90L | 3.5 | 12 | 200 | 130 | 165 | 12 | 137 | 215 | 90 | 56 | 125 | 30 | 10 | 14 | 182 | 140 | 43.3 | 12 | 175 | 96 | 70.5 | – | 325 | 50 | 19 | M8 | 27 | 32 | 8 | 24 | FF165 |

| 100L | 4 | 15 | 250 | 180 | 215 | 12 | 145 | 233 | 100 | 63 | 140 | 35 | 12 | 17 | 200 | 160 | 40 | 12 | 194 | 96 | 73.5 | – | 366 | 60 | 22 | M10 | 31 | 40 | 8 | 28 | FF215 |

| 112M | 4 | 15 | 250 | 180 | 215 | 12 | 155 | 256 | 112 | 70 | 140 | 35 | 12 | 17 | 235 | 190 | 45 | 13 | 217 | 96 | 76.5 | 200 | 384 | 60 | 22 | M10 | 31 | 40 | 8 | 28 | FF215 |

PM Evaporative Cooler Electro Motors

0,00 €Pump type OH1-According to API 610

0,00 €Usages:

- Oil and Gas

- Petrochemical

- Power Plant

Product features

Design:

- Single-casing, radially split between bearings

- Segmental ring section pumps with tie-rods

- Single suction Impeller

- Sealing between segments by O-rings

- Mechanical shaft seal with single, double or tandem seal

- No limitation for pressures, Spec. gravity and dimensions of casing

- Axial bearing necessary additionally to balancing device