Evaporative Cooler SE320

0,00 €| Power Supply | 220 – 240,50 v~Hz | 110 – 120,60 v~Hz |

| Current(high mode) | 2.2 A | 4.3 A |

| Current(low mode) | 1.8 A | 3.5 A |

| Energy class | D | D |

| Length | 650 mm | 650 mm |

| Width | 650 mm | 650 mm |

| Height | 770 mm | 770 mm |

| Net Weight | 43 kg | 43 kg |

| Gross Weight | 44 kg | 44 kg |

| Water Inlet | 1/4 inch | 1/4 inch |

| Electro static painting | √ | √ |

| Metal Type | Galvanized | Galvanized |

| Cooling pad type | Wood wool pad | Wood wool pad |

| Air outlet dim | 300 x 300 | 300 x 300 |

| Capacity | 1850 cfm | 1850 cfm |

| Power of electro-pump | 1/60 hp | 1/60 hp |

| Power of electro-motor | 1/3 hp | 1/3 hp |

| Function type | Centrifugal | Centrifugal |

| Water volume | 33 lit | 33 lit |

Evaporative Cooler SE400-UD

0,00 €| Power Supply | 220 – 240,50 v~Hz | 110 – 120,60 v~Hz |

| Current(high mode) | 2.6 A | 5.2 A |

| Current(low mode) | 1.2 A | 2.3 A |

| Energy class | D | D |

| Length | 730 mm | 730 mm |

| Width | 730 mm | 730 mm |

| Height | 870 mm | 870 mm |

| Net Weight | 49 kg | 49 kg |

| Gross Weight | 50 kg | 50 kg |

| Water Inlet | 1/4 inch | 1/4 inch |

| Electro static painting | √ | √ |

| Metal Type | Galvanized | Galvanized |

| Cooling pad type | Wood wool pad | Wood wool pad |

| Air outlet dim | 350 x 345 | 350 x 345 |

| Capacity | 2800 cfm | 3360 cfm |

| Power of electro-pump | 1/60 hp | 1/60 hp |

| Power of electro-motor | 1/3 hp | 1/3 hp |

| Function type | Centrifugal | Centrifugal |

| Water volume | 46 lit | 46 lit |

Evaporative Cooler SE500B

0,00 €| Power Supply | 220 – 240,50 v~Hz | 110 – 120,60 v~Hz |

| Current(high mode) | 4.1 A | 8.1 A |

| Current(low mode) | 1.8 A | 3.5 A |

| Energy class | B | B |

| Length | 870 mm | 870 mm |

| Width | 870 mm | 870 mm |

| Height | 1030 mm | 1030 mm |

| Net Weight | 74 kg | 74 kg |

| Gross Weight | 75 kg | 75 kg |

| Water Inlet | 1/4 inch | 1/4 inch |

| Electro static painting | √ | √ |

| Metal Type | Galvanized | Galvanized |

| Cooling pad type | Wood wool pad | Wood wool pad |

| Air outlet dim | 490 x 480 | 490 x 480 |

| Capacity | 3900 cfm | 4860 cfm |

| Power of electro-pump | 1/60 hp | 1/60 hp |

| Power of electro-motor | 1/2 hp | 1/2 hp |

| Function type | Centrifugal | Centrifugal |

| Water volume | 66 lit | 66 lit |

Evaporative Cooler SE600-UD

0,00 €| Power Supply | 220 – 240,50 v~Hz | 110 – 120,60 v~Hz |

| Current(high mode) | 3.8 A | 7.5 A |

| Current(low mode) | 1.7 A | 3.3 A |

| Energy class | D | D |

| Length | 870 mm | 870 mm |

| Width | 870 mm | 870 mm |

| Height | 1030 mm | 1030 mm |

| Net Weight | 75 kg | 75 kg |

| Gross Weight | 76 kg | 76 kg |

| Water Inlet | 1/4 inch | 1/4 inch |

| Electro static painting | √ | √ |

| Metal Type | Galvanized | Galvanized |

| Cooling pad type | Wood wool pad | Wood wool pad |

| Air outlet dim | 490 x 480 | 490 x 480 |

| Capacity | 4000 cfm | 4800 cfm |

| Power of electro-pump | 1/60 hp | 1/60 hp |

| Power of electro-motor | 1/3 hp | 1/3 hp |

| Function type | Centrifugal | Centrifugal |

| Water volume | 66 lit | 66 lit |

Fan

0,00 €product specification

- Industrial Wall Fans appropriate for exposed outdoor use

- aluminum blades

- 110 to 220W Power consumption

- on 24 inch (600mm), 26 inch (650 mm) and 30 inch (750 mm) outer diameters

- 3 speed settings

- 11000-1400 rpm speed

- volume air-flow rate is 100 (CBM/Hr)

HA-200 Horizontal Warm Air Furnace

0,00 €The Warm Air Furnace HA-200 is a series of air Furnace that designed horizontally (cabins). This series is suitable for greenhouses due to its low height in compare with Vertical one. It’s designed in three models such as Natural Gas, Gasoline and Dual and generated as axial fan and centrifuge according to the order. The thermal capacity is 200.000 kcal/h and it provides heating space up to 2500 – 5000 m3.

The forced Air Furnace HA-200 is a heating system that through the electro fan installed next to the heat exchanger , after vacuum the cooling air from environment and passes cool air through heat exchanger , it causes heat exchanger passed through a heat surface to the environment either directly or through the channeling system. The heat exchanger brings the heat directly by the flame. The unit controls heating automatically and provide a benefit such as intelligent control and safety of fuel and oxygen in compare with past heating system. These forced Air Furnace operate with no open flame and no danger of carbon monoxide poisoning due to complete combustion.

HA-300 Horizontal Warm Air Furnace

0,00 €The Warm Air Furnace HA-300 is a series of air Furnace that designed horizontally (cabins). This series is suitable for greenhouses due to its low height in compare with Vertical one. It’s designed in three models such as Natural Gas, Gasoline and Dual and generated as axial fan and centrifuge according to the order. The thermal capacity is 300.000 kcal/h and it provides heating space up to 2500 – 7500 m3.

The forced Air Furnace HA-300 is a heating system that through the electro fan installed next to the heat exchanger , after vacuum the cooling air from environment and passes cool air through heat exchanger , it causes heat exchanger passed through a heat surface to the environment either directly or through the channeling system.

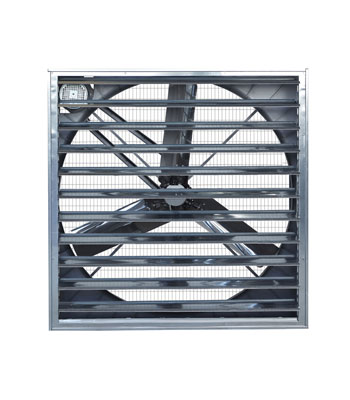

Industrial Fans NTA3140

0,00 €The 3Blade 140Fans Niroo Tahvieh Alborz Industrial Fans NTA3140, with the quantity of air flow 44100 m3 has a standard certified. In order to ventilate and proper airflow, industrials fan can be used in areas such as Poultry Farm’s halls, greenhouse, and industrial halls. This unit constructed on steel fan blade and resistance to corrosion and balanced with a fully automatic machine, in order to prevent unwanted vibration. The damper blade position is to be such as to prevent the entry of dust, dirt, and light. A typical centrifugal technology uses automatic duct dampers to open and close.

Industrial Fans NTA6100

0,00 €The 6Blade 100Fans Niroo Tahvieh Alborz Industrial Fans NTA6100, with the quantity of air flow 18700 m3 has a standard certified. In order to ventilate and proper airflow, industrials fan can be used in areas such as Poultry Farm’s halls, greenhouse, and industrial halls. This unit constructed on steel fan blade and resistance to corrosion and balanced with a fully automatic machine, in order to prevent unwanted vibration. The damper blade position is to be such as to prevent the entry of dust, dirt, and light. A typical centrifugal technology uses automatic duct dampers to open and close.

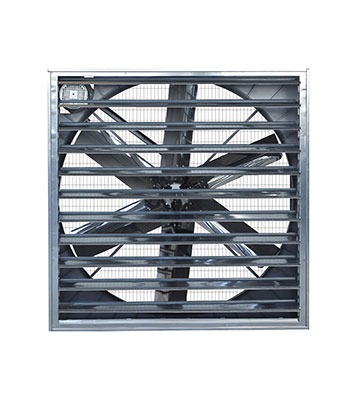

Industrial Fans NTA6140

0,00 €The 6Blade 140Fans Niroo Tahvieh Alborz Industrial Fans NTA6140, with the quantity of air flow 45380 m3 has a standard certified. In order to ventilate and proper airflow, industrials fan can be used in areas such as Poultry Farm’s halls, greenhouse, and industrial halls. This unit constructed on steel fan blade and resistance to corrosion and balanced with a fully automatic machine, in order to prevent unwanted vibration. The damper blade position is to be such as to prevent the entry of dust, dirt, and light. A typical centrifugal technology uses automatic duct dampers to open and close.

KHG-100 Vertical Warm Air Furnace

0,00 €The Warm Air Furnace KHG-100 is designed in three models such as Natural Gas, Gasoline and Dual for large heating space including Sport Halls, industrial halls, and public and etc. The thermal capacity of is 100.000 kcal/h it provides heating space up to 1000 – 2500 m3. The hot Air Furnace KHG-100 is a heating system that through the electro fan installed next to the heat exchanger , after vacuum the cooling air from environment and passes cool air through heat exchanger , it causes heat exchanger passed through a heat surface to the environment either directly or through the channeling system. The heat exchanger brings the heat directly by the flame. The unit controls heating automatically and provide a benefit such as intelligent control and safety of fuel and oxygen in compare with past heating system. These forced Air Furnace operate with no open flame and no danger of carbon monoxide poisoning due to complete combustion.

Exhaust gas is emitted as a result of the combustion of fuels is controlled. The heat exchanger is connected to chimney through the tube in order to release of combustion gases. These units in a large model can be connected to the particular channel in order to heat transfer.

KHG-200 Vertical Warm Air Furnace

0,00 €The Warm Air Furnace KHG-200 is designed in three models such as Natural Gas, Gasoline and Dual for large heating space including Sport Halls, industrial halls, and public and etc. The thermal capacity of is 200.000 kcal/h it provides heating space up to 2000 – 5000 m3.

The hot Air Furnace KHG-200 is a heating system that through the electro fan installed next to the heat exchanger , after vacuum the cooling air from environment and passes cool air through heat exchanger , it causes heat exchanger passed through a heat surface to the environment either directly or through the channeling system. The heat exchanger brings the heat directly by the flame.