Chicken Farming Equipment Karno Feed Pan

0,00 €Technical Specifications:

• Fiber glass bipartite hopper for easy cleaning

• Electrical winch 1-1/5 ton for easy elevating of feeding line

• Portable optical sensor on the feeding line

• Electro Motor Gearbox 1KW-3 phases

• High quality galvanized pipe with high quality that is cut with a special device and prevents the movement of plate on the pipe

Chicken Farming Equipment Karno Nipple Drinking System

0,00 €Technical Specifications:

• Full-strength nipple with 360 degree rotation

• 10-2 to 15 chicken phones for each nipple and 10 to 12 nipples for mother and pill

• Intervals between nipples are in 25 and 30 cm

• models High resistance to rust and corrosion

Chicken Farming Equipment Layer Cage

0,00 €Fully Automatic Chicken Cage System with Stacking Battery with Barrel

This cage is made of high quality galvanized sheets and wires. The distance between the base cages is 60 cm, which increases the cage’s resistance.

The dimensions of each cell are 60 * 60 cm and 40 cm high, suitable for 9 chicken heads – the cage has a wagon system, a child bar, a nipple drinker, an egg collecting system and an elevator.

The design of the cage is such that it has the least problem in the transfer of fertilizer out of the hall and there is no problem in moving the air between the cells.

Manufactured fertilizer and egg bar making system in Italy.

Chicken Farming Equipment Poultry Smart Control System

0,00 €Specifications:

• Controlled ventilation system types ( transverse , transport and tunnel )

• Variable speed fan control separately

• Control Systems

• Controlled cooling system

• Lighting Control

• Control of Power Systems

• Angle control valves Aynlt

• Control the amount of intake air

• Humidity -controlled room

• Control of harmful gases ( ammonia , carbon dioxide , hydrogen sulfide, carbon Mvnksyd )

• Controlling the temperature inside and outside the hall sensors embedded

• Antbaq with all the breeds of poultry and poultry breeder and different climatic conditions

• Room temperature and humidity logging capabilities

• PC connectivity and control from any location in hall

• Equipped with alarms and warning systems

• Send the same SMS to multiple lines

• Visibility and the amount of feed water per day for the entire period

Chicken Farming Equipment Poultry Smart Control System

0,00 €Specifications:

• Controlled ventilation system types ( transverse , transport and tunnel )

• Variable speed fan control separately

• Control Systems

• Controlled cooling system

• Lighting Control

• Control of Power Systems

• Angle control valves Aynlt

• Control the amount of intake air

• Humidity -controlled room

• Control of harmful gases ( ammonia , carbon dioxide , hydrogen sulfide, carbon Mvnksyd )

• Controlling the temperature inside and outside the hall sensors embedded

• Antbaq with all the breeds of poultry and poultry breeder and different climatic conditions

• Room temperature and humidity logging capabilities

• PC connectivity and control from any location in hall

• Equipped with alarms and warning systems

• Send the same SMS to multiple lines

• Visibility and the amount of feed water per day for the entire period

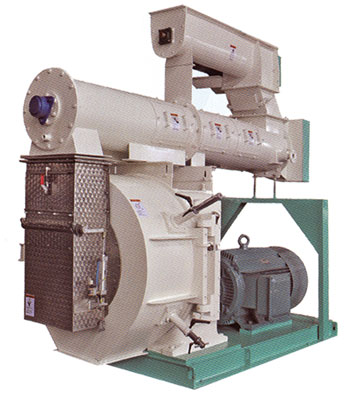

Chicken manure pellet machine

Khazar Electric in line with its policies, has started to setup its own factories for recycling and profitability of its products.

Chocolate Enrober & Cooling Tunnel

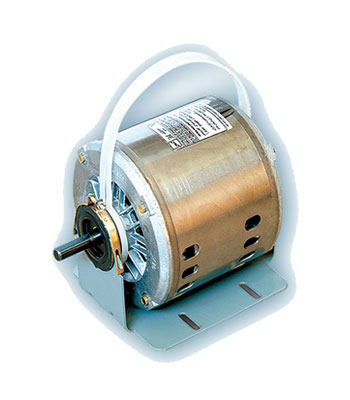

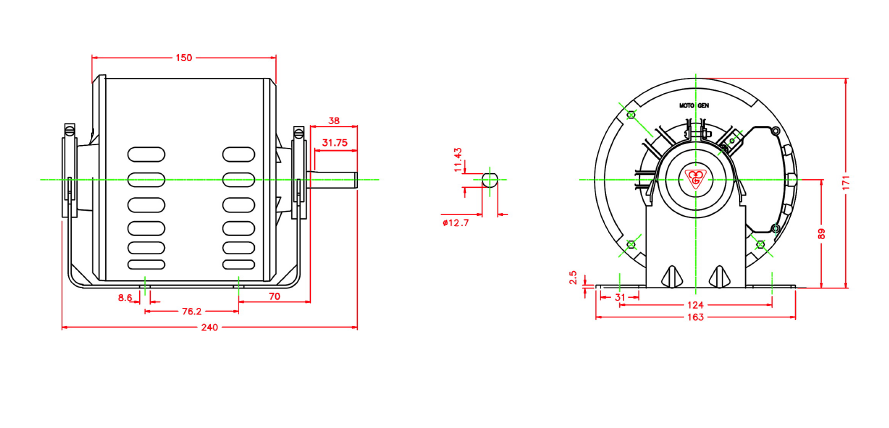

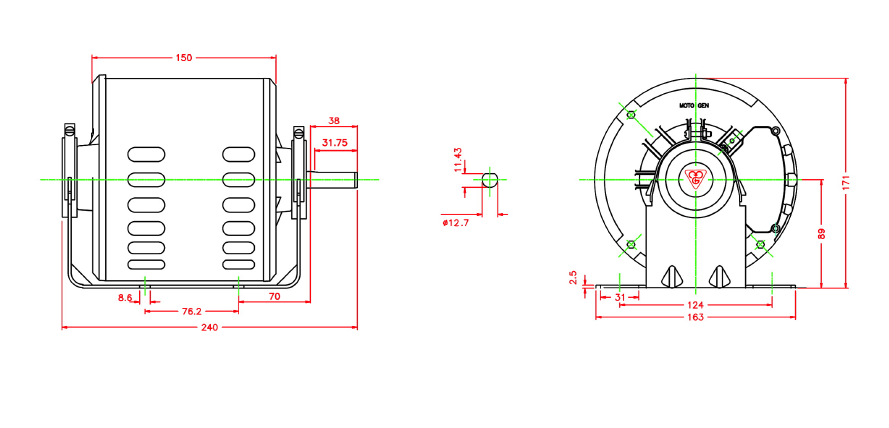

0,00 €Circulator Pump Split Phase Electro Motors

0,00 €Product Specification

| Type | Frame size | Output Power | Output Power | Rated Voltage | Speed in rated load | Rated Current | Rated Torque | Power factor | Starting / Rated Current | Starting / Rated Torque | Break down / Rated Torque | Inertia moment | Poles |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SP 56-4A | 56 | 0.124 | 1/6 | 220 | 1425 | 2 | 0.83 | 0.612 | 6.35 | 1.9 | 2.38 | 0.001581 | 1 |

| SP 56-4 | 56 | 0.25 | 1/3 | 220 | 1425 | 2.5 | 1.67 | 0.781 | 10.8 | 2.48 | 1.87 | 0.002488 | 1 |

| SP56-4B | 56 | 0.124 | 1/6 | 220 | 1425 | 1.4 | 0.83 | 0.754 | 8.26 | 1.96 | 2.1 | 0.002034 | 1 |

| SP 56-4/6 | 56 | 0.25/0.07 | 1/3 / 1/10 | 220 | 1425/950 | 2.5/1.6 | 1.67/0.75 | 0.781/0.565 | 9.1 | 2 | 1.83/2.67 | 0.002488 | 1 |

Circulator pump Split-phase electromotors

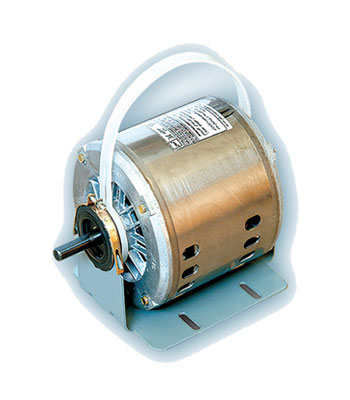

0,00 €Product Specification

| Type | Frame size | Output Power | Output Power | Rated Voltage | Speed in rated load | Rated Current | Rated Torque | Power factor | Starting / Rated Current | Starting / Rated Torque | Break down / Rated Torque | Inertia moment | Poles |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SP 56-4A | 56 | 0.124 | 1/6 | 220 | 1425 | 2 | 0.83 | 0.612 | 6.35 | 1.9 | 2.38 | 0.001581 | 1 |

| SP 56-4 | 56 | 0.25 | 1/3 | 220 | 1425 | 2.5 | 1.67 | 0.781 | 10.8 | 2.48 | 1.87 | 0.002488 | 1 |

| SP56-4B | 56 | 0.124 | 1/6 | 220 | 1425 | 1.4 | 0.83 | 0.754 | 8.26 | 1.96 | 2.1 | 0.002034 | 1 |

| SP 56-4/6 | 56 | 0.25/0.07 | 1/3 / 1/10 | 220 | 1425/950 | 2.5/1.6 | 1.67/0.75 | 0.781/0.565 | 9.1 | 2 | 1.83/2.67 | 0.002488 | 1 |

Clutch Bearings Ball Bearing

0,00 €We provide clutch bearings assemblies in both metric and inch nominal series. These are corrosion resistant and perform even on high speed with ease. The clutch bearing is similar to a roller bearing, but instead of allowing the elements to roll freely in both directions the rolling elements lock when rolled the opposite direction. Clutches have three main tasks to perform overrunning, indexing and backstopping. The clutch consists of a series of cam shaped steel wedges

Each clutch is placed at an angle to permit rotation in one direction, yet provides instantaneous backstopping in the other. It offers optimal running surfaces, compensates for thermal expansion, minimum energy consumption and superior speed & load carrying ability. Clutch bearings are applied to belt pulleys and chain wheels and as simple bearing support, backstop and overrunning clutch.

CNC Machine BIESSE ROVER K

0,00 €The innovative ATS work table boasts a universal design for superb flexibility and easy configuration.

The quick-coupling system ensures fast and easy replacement of the vacuum modules and the Uniclamps, used to lock narrow and particularly thick pieces in position.

Uniclamp clamps with pneumatic system.

Different references for the machining of multiple components.

The Pick Up station supports automatic tool-holder rack tooling.

Thanks to the 16 position tool-holder rack, tools and aggregates are always available, without the need for operator intervention when moving from one machining process to the next.

Cold Press Caliber 180 Production line

0,00 €The cold press oil extraction devices with power consumption 7. 5 kW 3-phase power works and life of at least five years has been set. Press 180 with high efficiency can catch the last of the oil lies in variety of oilseeds, the device is unrivaled in the world. For example, the device is capable of up to 42% of canola and sesame oil make up 52%.

The device is capable of drawing oil without causing environmental pollution and daily audio from 3 to 5 tons of grain to make oil and meal.