Annealed Stranded Copper Conductors

0,00 €Cross Section

- 0.5mm2 ∼ 300 mm2

Technical Specification

- Multi Strand

- Annealed

- Resistance Table II ,III and IV in BS EN 60228: 2005

Basbar

0,00 €Usage

Excellent electrical and thermal conductivity Good workability, drawability, corrosion and weathering resistancy Applicable to distribution panels.

Cathode Steel & Products

0,00 €The greatest Tank Bioleaching method in copper cathode production in the world is now constructed by Iranian Babak Copper Co. on a location 23 km away from Shahr-E-Babak city with nominal capacity of 50,000 tons a year. The chemical studies, pilot and process designing are done by EPCM, a Canadian company, and its executional operations have been started on Aug-17-2011 and hopefully will be inaugurated in mid-2016.

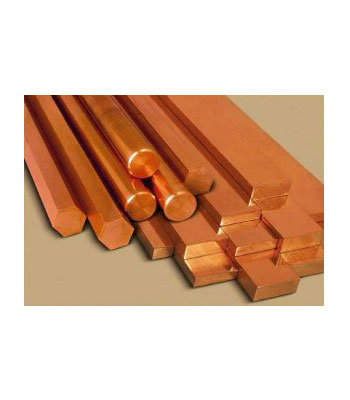

Copper sections

0,00 €USAGE

Copper sections

0,00 €USAGE

Copper sections

0,00 €USAGE

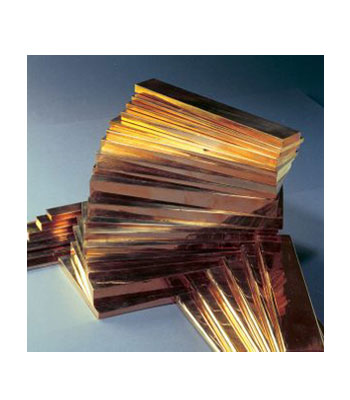

Copper Sheet and strip

0,00 €CSP is the most reputable name in manufacturing and supplying outstanding quality copper and copper alloy sheets in Iran. High-quality raw materials are used in our manufacturing plant for fabricating excellent performing copper products.

The wide range of copper products offered by CSP includes copper and copper alloy sheet & plate.

The wide range of copper sheets is used at large q uantities in diverse industrial segments for different applications.

USAGE

TPC:

These copper sheets & plates have excellent electrical and thermal conductivity, and are used mainly in electrical appliances.

DLP-DHP:

Good workability, draw-ability and weldability along with high thermal conductivity are the main characteristics of this category of copper sheets, which are used i n HVAC (heating, ventilation and air conditioning) systems.

Cu-Sn:

This category of products is suitable for cooling system (i.e. automobile radiator). With 0.1-0.18 percent of Tin it has a good consistency up to 300° C.

Note: Other grades of copper alloys are available upon request.

Copper Sheet and strip

0,00 €CSP is the most reputable name in manufacturing and supplying outstanding quality copper and copper alloy sheets in Iran. High-quality raw materials are used in our manufacturing plant for fabricating excellent performing copper products. The wide range of copper products offered by CSP includes copper and copper alloy sheet & plate. The wide range of copper sheets is used at large q uantities in diverse industrial segments for different applications.

Copper Sheet and strip

0,00 €CSP is the most reputable name in manufacturing and supplying outstanding quality copper and copper alloy sheets in Iran. High-quality raw materials are used in our manufacturing plant for fabricating excellent performing copper products.

The wide range of copper products offered by CSP includes copper and copper alloy sheet & plate.

The wide range of copper sheets is used at large q uantities in diverse industrial segments for different applications.

USAGE

TPC:

These copper sheets & plates have excellent electrical and thermal conductivity, and are used mainly in electrical appliances.

DLP-DHP:

Good workability, draw-ability and weldability along with high thermal conductivity are the main characteristics of this category of copper sheets, which are used i n HVAC (heating, ventilation and air conditioning) systems.

Cu-Sn:

This category of products is suitable for cooling system (i.e. automobile radiator). With 0.1-0.18 percent of Tin it has a good consistency up to 300° C.

Note: Other grades of copper alloys are available upon request.

Copper Sheet and strip

0,00 €CSP is the most reputable name in manufacturing and supplying outstanding quality copper and copper alloy sheets in Iran. High-quality raw materials are used in our manufacturing plant for fabricating excellent performing copper products. The wide range of copper products offered by CSP includes copper and copper alloy sheet & plate. The wide range of copper sheets is used at large q uantities in diverse industrial segments for different applications.

Copper Sheet and strip

0,00 €CSP is the most reputable name in manufacturing and supplying outstanding quality copper and copper alloy sheets in Iran. High-quality raw materials are used in our manufacturing plant for fabricating excellent performing copper products.

The wide range of copper products offered by CSP includes copper and copper alloy sheet & plate.

The wide range of copper sheets is used at large q uantities in diverse industrial segments for different applications.

USAGE

TPC:

These copper sheets & plates have excellent electrical and thermal conductivity, and are used mainly in electrical appliances.

DLP-DHP:

Good workability, draw-ability and weldability along with high thermal conductivity are the main characteristics of this category of copper sheets, which are used i n HVAC (heating, ventilation and air conditioning) systems.

Cu-Sn:

This category of products is suitable for cooling system (i.e. automobile radiator). With 0.1-0.18 percent of Tin it has a good consistency up to 300° C.

Note: Other grades of copper alloys are available upon request.

Copper Sheet and strip

0,00 €CSP is the most reputable name in manufacturing and supplying outstanding quality copper and copper alloy sheets in Iran. High-quality raw materials are used in our manufacturing plant for fabricating excellent performing copper products. The wide range of copper products offered by CSP includes copper and copper alloy sheet & plate. The wide range of copper sheets is used at large q uantities in diverse industrial segments for different applications.