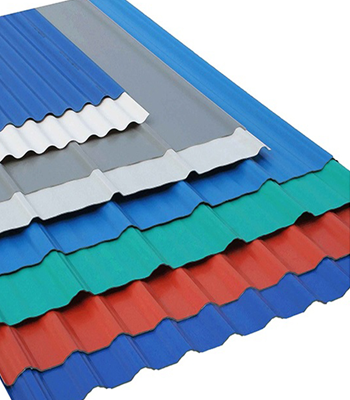

Metals & Minerals Galvanized Color Coated Sheet

0,00 €Galvanized sheets are painted for aesthetics, increased resistance and reduced corrosion. If the production of colored galvanized sheets is due to their appearance and decoration, the color coating is of great importance. However, if it is to enhance corrosion resistance, the sheet rust is minimized.

Metals & Minerals Galvanized sheets

0,00 €Hot dip galvanizing has been used for over 150 years as a successful commercial method in the world for protecting steel sheets against corrosion. Galvanized products have long service life and high corrosion resistance.

Pellet

0,00 €Pellet is the final product of the pelletizing and is the raw material for processes of pig iron production in the blast furnace and production of sponge iron by the various reduction methods. To use pellet, its quality for transportation should be desired. In common terms, pellet means balls produced from iron ore and other additives that are first smooth and then are hardened and is used for reduction by the traditional method of producing iron in the blast furnace or by the different methods of direct reduction.

Pig Iron

0,00 €Blast furnace is same as blast furnace cast iron that should be changed in order to be transformed to other iron derivatives. Blast furnace cast iron usually has impurities that are again melted to be changed into other ingot or casting parts and is casted again after Refining and alloying operations.