| Metallisation | 92.0 – 96.0% |

| Fe (Total) | 86.1 – 93.5% |

| Fe (Metallic) | 81.0 – 87.9% |

| C | 1.0 – 4.5% |

| S | 0.001 – 0.03% |

| P2O5 | 0.005 – 0.09% |

| Gangue* | 3.9 – 8.4% |

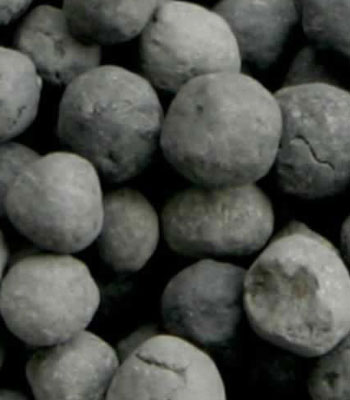

| Size (typical) | 4 – 20 mm |

| Apparent Density | 3.4 – 3.6 t/m3 |

| Bulk Density | 1.6 – 1.9 t/m3 |

* residual unreduced oxides, mainly SiO2 and Al2O3,, but also CaO, MgO, MnO, etc.

Benefits in steelmaking

For further information about DRI and its advantages in the EAF, see our Fact Sheet:

Shipping and handling of DRI

Shipping and handling of DRI

Being a highly reduced material, DRI has a tendency to re-oxidise, an exothermic reaction. Thus, without appropriate precautions being taken in its handling, transport and storage, there is a risk of self-heating and fires. The International Maritime Organisation’s International Maritime Solid Bulk Cargoes Code classifies DRI – Direct Reduced Iron (B) – as Group B (cargo with chemical hazard) and class MHB (material hazardous only in bulk) and requires that DRI be shipped under an inert atmosphere, usually nitrogen.

Further information can be found in IIMA’s Logistics Guide DRI: Guide for Shipping, Handling and Storage (planned 2018).

Direct reduction of iron is the removal of oxygen from iron ore or other iron bearing materials in the solid state, i.e. without melting, as in the blast furnace. The reducing agents are carbon monoxide and hydrogen, coming from reformed natural gas, syngas or coal. Iron ore is used mostly in pellet and/or lumpy form.

The chemical reactions involved in the direct reduction of iron are the following:

With H2

3Fe2O3 + H2 → 2Fe3O4 + H2O

Fe3O4 + H2 → 3 FeO + H2O

FeO + H2 → Fe + H2O

With CO

3Fe2O3 + CO →2Fe3O4 + CO

Fe3O4 + CO → 3 FeO + CO2

FeO + CO → Fe + CO2

With Solid Carbon in reaction

CO2 + C → 2CO

Direct Reduction Processes

There are several processes for direct reduction of iron ore:

- gas-based shaft furnace processes (Midrex® and Energiron being the main ones) – accounting for 75.8% of 2019 DRI production (total 108.1 million tonnes);

- gas-based fluidized bed processes (the Finmet / Finored process being the only commercial scale one in operation) – accounting for 0.2% of 2019 DRI production

- coal based rotary kiln furnaces (mainly in India) – accounting for 24% of 2019 production.

Generic illustrations of the types of process are shown in the graphics below.

Overview of direct reduction process types

Direct reduction furnace types

Direct reduction processes for iron

Illustrations of the principal processes are shown below. The Midrex® and Energiron gas-based processes use predominantly iron ore pellets as feedstock, but sometimes with inclusion of lump ore in the furnace charge. The Finmet / Finored gas-based process utilizes iron ore fines as feedstock. The SLRN coal-based rotary kiln process uses lump ore and, increasingly, pellets as feedstock. There are variants of these processes which are described on the websites of the various technology providers.

Midrex® process

Energiron process

Standard Energiron process flowsheet

Finmet / Finored Megatrain process

SLRN process

SLRN direct reduction process flowsheet

Shipping and handling of DRI

Shipping and handling of DRI

Reviews

There are no reviews yet.