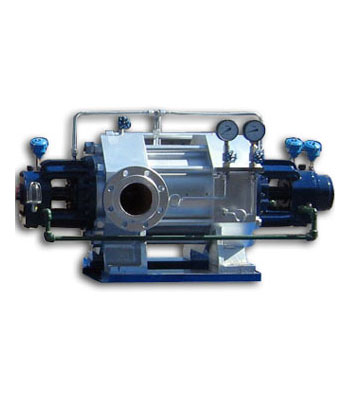

Features:

- Optimized hydraulics for high efficiency

- Interchange ability of parts simplifies stock keeping

| Type of bearing | Ball, Rolling and plain bearings |

| Casing partition | Radially split |

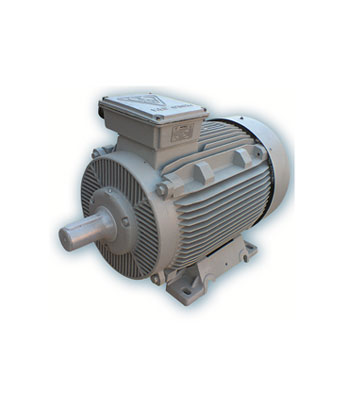

| Drive frequency | 50 Hz /60 Hz |

| Type of drive | Electric motor, Diesel Engine |

| Drive voltage | Low, Medium and high voltage |

| No. of impeller entries | Single entry |

| Type of installation | Long-coupled |

| Type of coupling | Direct |

| Type of lubrication | Grease / Oil lubricant |

| Max. permissible fluid temperature | 200 °C |

| Min. permissible fluid temperature | -20 °C |

| Nozzle position | Side – Top ( other on request ) |

| Pump set location | Dry installed |

| Suction characteristics | Non-priming |

| Type of casing | Diffuser casing |

| Type of impeller | Closed, Radial |

| Type of connection | Flange |

| Maximum head | Up to 100 m per stage |

| Installation position | Horizontal |

| Shaft seal type | Gland packing, Mechanical seal |

| Main applications | Energy, Industry and process engineering, Mining |

| Casing material | Table H-1 of API610 |

| Maximum discharge-side pressure | 150 bar |

| Maximum drive rating | 1800 kW |

| Type of installation | Stationary |

| Maximum flow rate | 900 m³/h |

| Minimum flow rate | 10 m³/h |

| Maximum speed of rotation | 3500 1/min |

Usages:

Applications:

Pumping of:

- Pumping of different clean hydrocarbons

Exploitation:

- Refining plants

- Petrochemical plants

Operating ranges:

- Capacity: up to 900 m3/h

- Head: up to 2600 m

- Pressure: up to 270 bar

- Temperature: -20 to +210 0C

Advantages:

- Casing stiffness high

- Single casing

- Lower weight, compared with barrel execution casing

Reviews

There are no reviews yet.