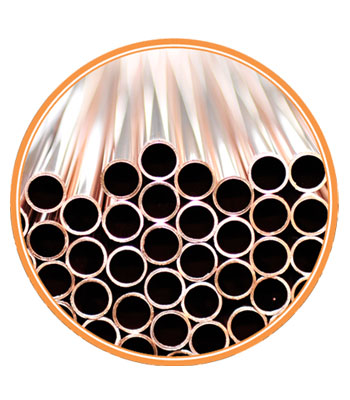

Sanitary Tubes – Size Range

Since 1940’s, copper has become the pre-eminent plumbing material in the developed countries of the world. Nowadays contamination of drinking water via plastic piping increasingly recognizes as a potentially serious problem.

The unique characteristics of copper piping combining long trouble-free service life, safety and weight savings due to the ability to use smaller diameters and its recyclability even after long time used readily explain the success of copper in building applications.

The main properties that make copper tube as a preferred material for domestic water services include the following:

Ease of Installation, Ability to be easily Joined and Manipulated, High Strength beside good Toughness and Ductility, Ultra cleaned inner surfaces, Corrosion Resistance, Suitability for use with Potable and Other waters, Potential as Bactericide, Bio-Fouling Resistance and availability in a wide metric sizes compatible with fitting and other system components.

In addition, the ease of fabrication and installation of copper tubing, results in improved cost-effectiveness of copper.

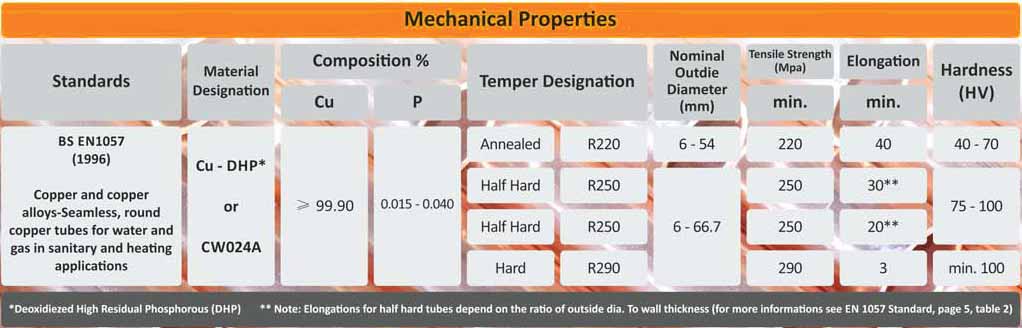

plant, the copper tubes are intended for water and gas in sanitary and heating applications usually manufactured in accordance with specifications given in ASTM (B88) and European Norm standard (EN 1057).

EN 1057 specification is applicable to seamless copper tubes having an outside diameter from 6 mm up to and including 54 mm for distributing networks for hot water and cold water, hot water heating systems (including under floor heating systems), solar system, domestic gas and liquid fuel distribution and waste water sanitation.

Reviews

There are no reviews yet.