Textile waste water treatment

0,00 €Introduction

PNF Co has an innovational combination of methods to meet textile industries requirement. The most important advantages of the applied technologies are feasibility and efficiency in this problem.

In electro-oxidation process, a kind of electric current applied into the electrolytic reactor causes the colloidal impurities to de-stabilize, resulting in agglomeration and flotation and subsequent removal. Dissolved impurities contributing BOD/COD also get oxidized due to the oxidizing agents released by the electrolytic solution which changes them into a state that is either less colloidal and less emulsified (or soluble). Also, Color has been decreased during this process. PNF Co is using a special coated plate and also power source to improve the operation and also decrease power consumption of the electro-oxidation unit. Electro dialysis unit also is used to remove salts and other ionized contaminants and makes the water suitable for re use.

Traffic Paint

0,00 €Introduction

This product is traffic paint based on thermoplastic acrylic nanocomposite resin. In nanocomposites inorganic filler is dispersed within a polymer matrix at a nanoscale level, thus the clay layer could be intercalated or exfoliated into the polymer to form polymer/clay nanocomposites. The paint has a fast-drying time, high durability, excellent resistance to various weather conditions and excellent adhesion to surfaces covered with asphalt and cement.

UPVC Door and Window Profiles containing Nanoparticles

0,00 €Introduction

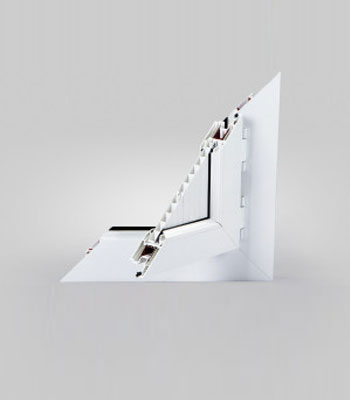

UPVC Nanocomposite Profiles

0,00 €Introduction

This product is unplasticized polyvinyl chloride (UPVC) nanocomposite profile containing nanoparticles. UPVC is among the widely used polymers in building construction which is the more suitable option compared to metal and wooden profiles due to features such as high durability and performance, easy formability, low thermal expansion, prevention of the energy loss and non-flammability. However, the brittleness and loss of color during exposure to UV radiation are some disadvantages of these profiles. as a solution, nanomaterials are added to the UPVC which improve the impact strength of the product.

UPVC Rainwater Pipe

0,00 €Introduction

Rainwater pipes are used to transfer the rain and snow water from roof of the buildings. Polyvinyl chloride (PVC) is kind of useful plastics in construction and buildings. By adding lubricants, this material will become softer and more flexible than plastics. If no lubricant and plasticizer is added, UPVC is obtained. Chemical resistance of this polymer makes it interesting for a variety of industries especially pipe industry. Usage of UPVC includes sewer pipelines, water mains and potable water services, power and telecommunication cables. These pipes are supposed to have chemical and corrosion resistance, high elasticity module and toughness, long term tensile strength and abrasion resistance, but they may become brittle exposed to cold atmosphere. In addition, they tend to deform and lose their strength in high temperature conditions. These pipes have been given better properties by addition of nanoparticles.

UPVC Sewer Pipes

0,00 €Introduction

Nowadays, the most of sewage pipes are made of UPVC. Polyvinyl chloride (PVC) is one of the most widely used plastics in construction and buildings which has various applications. Addition of lubricants makes this material softer and more flexible than plastics. If no lubricants or plasticizers are added to it, the resulting material is known as UPVC. The chemical resistance of this polymer has made it suitable for wide applications in different industries, especially the pipe industry. These pipes are supposed to have chemical and corrosion resistance, high elasticity modulus and flexibility, long-term tensile strength, high strength to weight ratio and wear resistance. However, it should be noted that these pipes can be fragile when exposed to cold weather. Besides, they can be deformed and lose their strength because of high temperature. Addition of appropriate nanoparticles can obviate these deficiencies and improve their properties.

UPVC Water Supply Pipe

0,00 €Introduction

Water pipes are mainly used for water supply, sewage and drainage applications. These pipes are made of polyvinyl chloride (PVC) which widely used in buildings. Addition of lubricants makes this material softer and more flexible than plastics. If no lubricants or plasticizers are added to it, the resulting material is known as UPVC. The chemical resistance of this polymer has made it suitable for wide applications in different industries, especially the pipe industry. These pipes are supposed to have chemical and corrosion resistance, high elasticity modulus and flexibility, longterm tensile strength, high strength to weight ratio and wear resistance. However, it should be noted that these pipes can be fragile when exposed to cold weather. Besides, they can be deformed and lose their strength because of high temperature. Addition of appropriate nanoparticles can obviate these deficiencies and improve their properties.

Utensils with Golden Nanostructured Coating

0,00 €Introduction

- Tray

- Tea set

- Salad plate

- Soup bowl

- Catering dish

- Hot drinks holders

- Candlestick

Water-based Inkjet Ink Formulated with Pigment Nanoparticles

0,00 €Introduction

Ink is a liquid or paste that contains pigments or dyes and is used to color a surface to produce an image, text, or design. Ink can be a complex medium, composed of solvents, pigments, dyes, resins, lubricants, solubilizers, surfactants, particulate matter, fluorescents, and other materials. Pigment inks are used more frequently than dyes because they are more color-fast, but they are also more expensive, less consistent in color, and have limited color range than dyes. Pigments are solid, opaque particles suspended in ink to provide color. Pigment molecules typically link together in crystalline structures that are 0.1-2 μm in size and comprise 5-30 percent of the ink volume. Qualities such as hue, saturation, and lightness vary depending on the source and type of pigment.

Wear & Corrosion resistant Super hard Nanolayer & Nanocomposite Coatings

0,00 €Introduction

Wear- and corrosion-resistant super-hard nanolayer and nanocomposite coatings are widely applied onto the surface of the turbine and compressor blades in the oil, gas and aerospace industries as an alternative for the conventional coatings. It is worth mentioning that the deposition of above-mentioned coatings is performed by using a Hybrid PVD system which operates based on both cathodic arc and sputtering processes.